Garage is finished and all stuff has been sorted t a functional use and space. Next the truck comes back...hopefully tomorrow!

Friday, June 17, 2022

Sunday, May 8, 2022

After rerouting wires to where they are now safely routed thru the studs instead of hanging down over the out side of studs making putting up insulation and drywall impossible. So fter getting the last of the drywall up, yesterday I moved out everything that I could and the rest pushed to one side. Then I mopped and cleaned the cement. After that applied the base coat of cement sealant. I'm using a combo of Ghostshield products.

Ghostshield: Lithi-Tek 4500 Concrete Sealer/Densifier

Siloxa-Tek 8500 Ultra Concentrate

Next while the cement cured over the next 30 days, I tore down a big 20 foot long shelf on the right side of the garage as it blocked insulation and drywall which was the next project. Interesting enough the plastic bags holding the insulation bats sweated the floor in a few places that now have darker edges! I also had a hard time finding the insulation in our hardware and lumber supply chain stores. Gotta say the supply chain right now is pretty much not dependable.

With the shelf out insulation and some extra electrical sockets was next

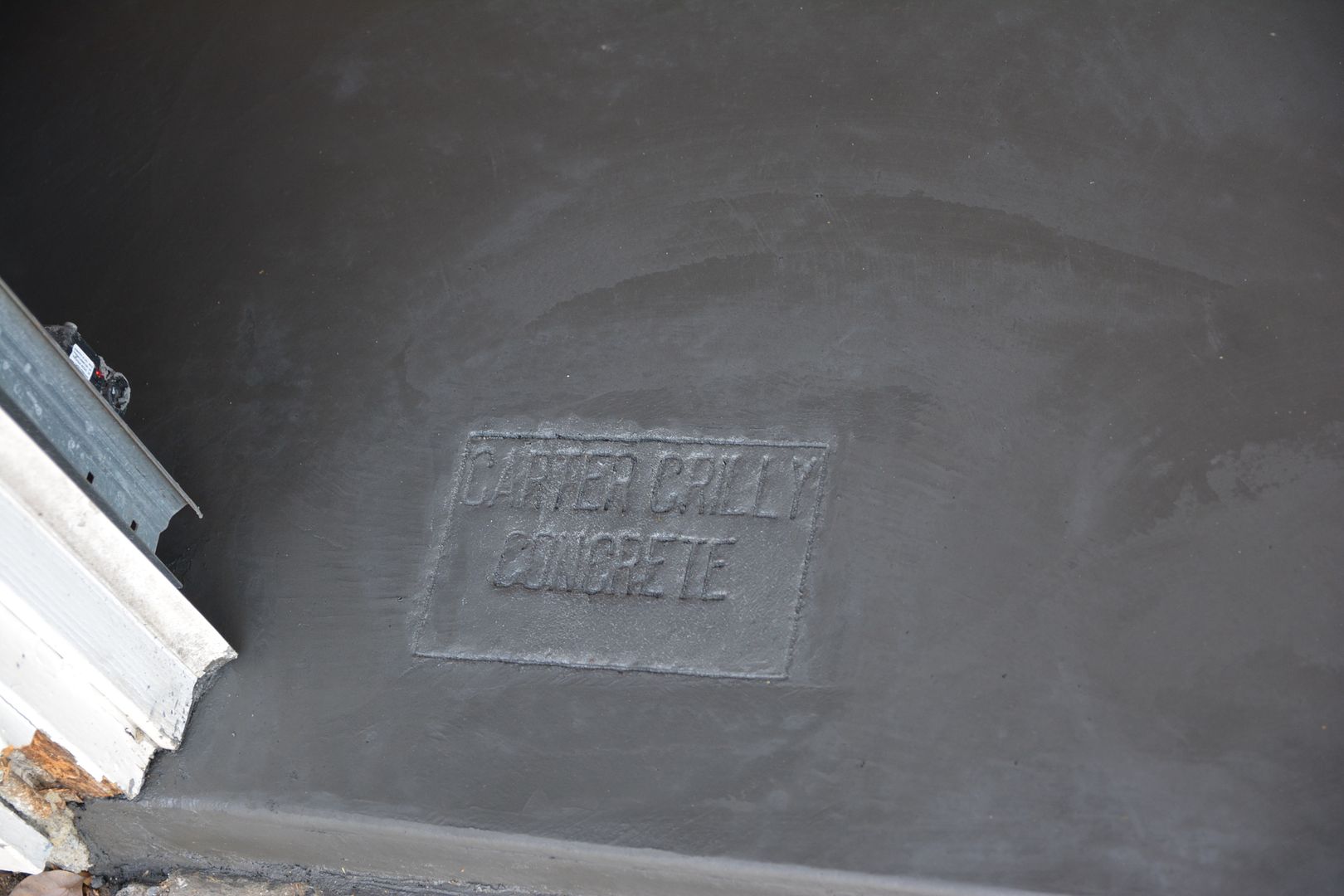

All that was under old slab was sand and roots. The slab was literally less than than an inch thick in places and poured on top if sand. Another two days were digging down deeper and removing a bunch of fairly thick tree roots coming from my neighbors fig tree.

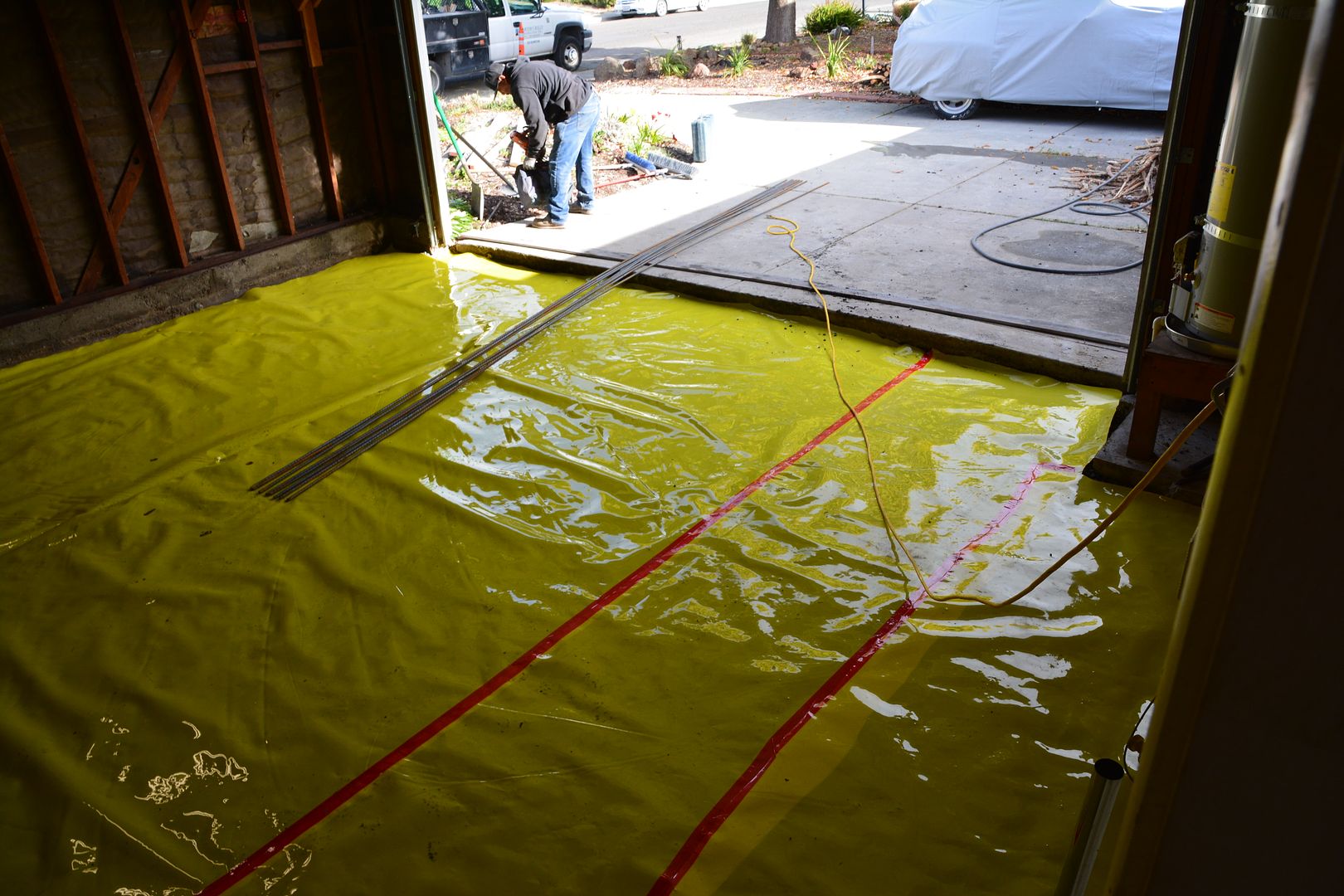

Then adding a base of packed gravel. followed by a water/vapor special plastic for cement, and rebar!

The last few months have been devoted to fixing the Garage. Between January and February I put most of the front end body panels. I had to order new passenger side and driver's side hinges which were lost in the mail delaying the hood going on. This was frustrating because in March the truck had to go outside! In the end it is sitting where it should be but not secured on. I got a nice water proof cover so it should be fine until I finish the Garage.

This was all necessary in order to gut the garage and have the busted up, non rebar fortified 1960 slab out, and replace with a new one. These photos show how the floor was lifted in the middle and broken over time by roots under it.

https://hosting.photobucket.com/images/cc214/stovens/IMG_20220321_131033043.jpg

Monday, January 24, 2022

Well it has been quite a few years since I have updated this post. Life, Divorce, Moving, and busy work schedule slowed me down to a crawl. But I am happy to say the truck continues. Will be posting more regularly as the weather warms up! Stay tuned. Below is the new fuel pump I recently added, my new dog Wednesday as my old guy passed a few years back, and pictures of the front boxed in frame and some custom welding to allow a notch in the frame for passenger side header to clear. What is too hard to get a picture of is the internal extra plates welded in that big notch that help add beef and anti-buckling there!

Thursday, April 30, 2009

Monday, February 2, 2009

.jpg)